Non-ideal compressible fluid dynamics

The gasdynamics of a fluid operating in a thermodynamic region near to or overlapping liquid-vapour equilibrium, as it is the case in Organic Rankine Cycle applications, may significantly differ from that of dilute gases under both a qualitative and quantitative point of view. As an example, figure 1 reports the optimal geometry for a supersonic straight-axis expander operating with siloxane fluid MDM (Octamethyl-trisiloxane, H24Si3O2C8), already in use in ORC, in the close proximity of the saturation curve. The expander is designed to attain a uniform parallel supersonic flow at Mach number 2.2 at the exit of the expander, a condition often encountered in ORC turbine blade. Two different designs are compared. In the upper portion of Figure 1, the nozzle geometry obtained from the Span-Wagner real gas model is reported; in the lower portion, the geometry obtained from the ideal gas model is shown. The two geometry attains the same exit Mach number, but the real gas design is significantly differ, thus indicating that non-ideal compressible fluid dynamic effects are of paramount relevance.

Figure 1: supersonic expansion of siloxane fluid MDM in the close proximity of the saturation curve. The expander is designed to attain an exit Mach number of 2.2 using the real-gas Span-Wagner model (top) and the ideal gas model (bottom).

The nozzle in Figure 1 was designed as the test chamber for the blow-down non-ideal compressible fluid dynamic wind tunnel TROVA, which is currently being commissioned at Politecnico di Milano. The experimental facility now allows to create a stationary supersonic flow at the exit of convergent-divergent nozzle for a short time (from 20ms to 100 ms), depending on the size of the component to be tested, using an upstream reservoir for the working fluid at high temperature (up to 400 ° C) and pressure (up to 50 bar), and a downstream reservoir at low temperature and pressure to condense the fluid. The working fluid is the siloxane MDM.

The heating and evaporation of the fluid is carried out by external electrical heaters, located over the surface of the high-pressure tank, in about one hour. Condensation is realized by means of a water cooling tower at the low pressure reservoir in less than one hour. The system is closed by a line to pump the condensed fluid to the high-pressure reservoir. The component under test is placed between the two tanks; the feeding pressure at the measurement section is controlled by a fast-response throttle valve. The system allows for testing at intervals of the order of one hour of machine parts (typically the vanes of the turbine) characteristic of full-scale industrial installations (eg 2 MW). In this case, test times are reduced but still compatible with available measurement techniques.

Figure 2: Overview of the TROVA experimental facility at Politecnico di Milano. The vertical-axis vessel is the high-pressure reservoir. The larger vessel is the low-pressure reservoir. The test section, namely, the convergent-divergent nozzle, is the pipe portion parallel to the low-pressure reservoir.

Nonclassical gasdynamics

In addition to quantitative departure from dilute gas dynamics, more striking qualitatitive difference are predicted to occur in the non-ideal compressible fluid dynamic region. The presence of well-known thermodynamic processes such as liquid-vapour transition or critical point phenomena may lead to the appearance of “exotic” wave fields including rarefaction shocks, mixed, composite and split waves. For example, mixed and split waves may form when the flow undergoes a phase transition. These waves are termed non classical waves, to be contrasted with compression shock waves and rarefaction isentropic waves usually encountered in (classical) gasdynamics.

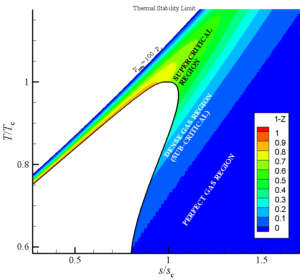

Figure 3: Non-ideal compressible fluid region for siloxane fluid MDM. The value of 1-Z, with Z compressibility factor Pv/RT, is shown in the single phase region. The saturation curve embeds the two-phase region (filled with white colour). The thermal stability limit is also indicated.

Note that for a polytropic, i.e., constant specific heats, ideal gas, only classical gasdynamics phenomena are thermodynamic admissible. Non classical behaviour is therefore expected to occur in highly non-ideal thermodynamic states only. Non classical behaviour in flows displaying liquid-vapour phase transition has been observed experimentally in 1986. In 1961, non classical rarefaction shock waves in allotropic phase changes in steel specimen have been reported. In 1942, Bethe speculated on the possibility for real fluids to exhibit non classical gasdynamics phenomena in the single-phase vapour region. By using the simple van der Waals model, he discovered that molecularly complex vapours may allow for non classical gasdynamics phenomena to occur in a thermodynamic region located in the vicinity of the liquid-vapour saturation curve and critical point, see figure 4. More recently, the existence of such a region for different fluids has been investigated using more accurate thermodynamic models. A number of molecularly complex hydrocarbons, perfluorocarbons and siloxanes have been identified which should exhibit non classical flow fields in the vapour phase. These fluids are usually called BZT vapours after the names of Bethe, Zel’dovich and Thompson. In the past sixty years numerous theoretical and numerical results have been published that investigate fundamental non classical gasdynamics phenomena as well as the possibility of taking advantages of non classical behaviour to increase the efficiency of turbomachinery already employing molecularly complex fluids, as it is the case of ORC.

Figure 4: the FAST non-ideal compressible fluid dynamic Ludwieg-tube at the Delft University of Technology.

Despite the numerous theoretical and numerical results and the potential advantages deriving from the exploitation of non classical gasdynamics phenomena in industrial processes, no experimental evidence of the existence of non classical phenomena in the vapour phase is available. In 1983, Borisov and collaborators claimed to have observed a rarefaction shock wave in Freon-13; however, the observed wave field is now believed to be related to both critical point and two-phase effects. In 2003, a non-ideal compressible fluid dynamic shock tube experiment at the University of Colorado at Boulder. The goal of the experiment was to provide an experimental proof of the occurrence of non classical gasdynamics behaviour in fluid PP10 (C13F22). Unfortunately, the experiment failed due to the thermal decomposition of the working fluid at the high temperature of operation. The FAST non-ideal compressible fluid dynamic Ludwieg-tube experimental facility is currently operational at the Delft University of Technology, the Netherlands. The design employs siloxanes, silicon oils currently used as working fluid in ORC. Similarly to the Boulder experiment, the FAST Ludwieg-tube experiment is aimed at demonstrating the existence of non classical phenomena in the vapour phase by measuring the propagation speed of a rarefaction shock wave in a quasi-one-dimensional configuration.